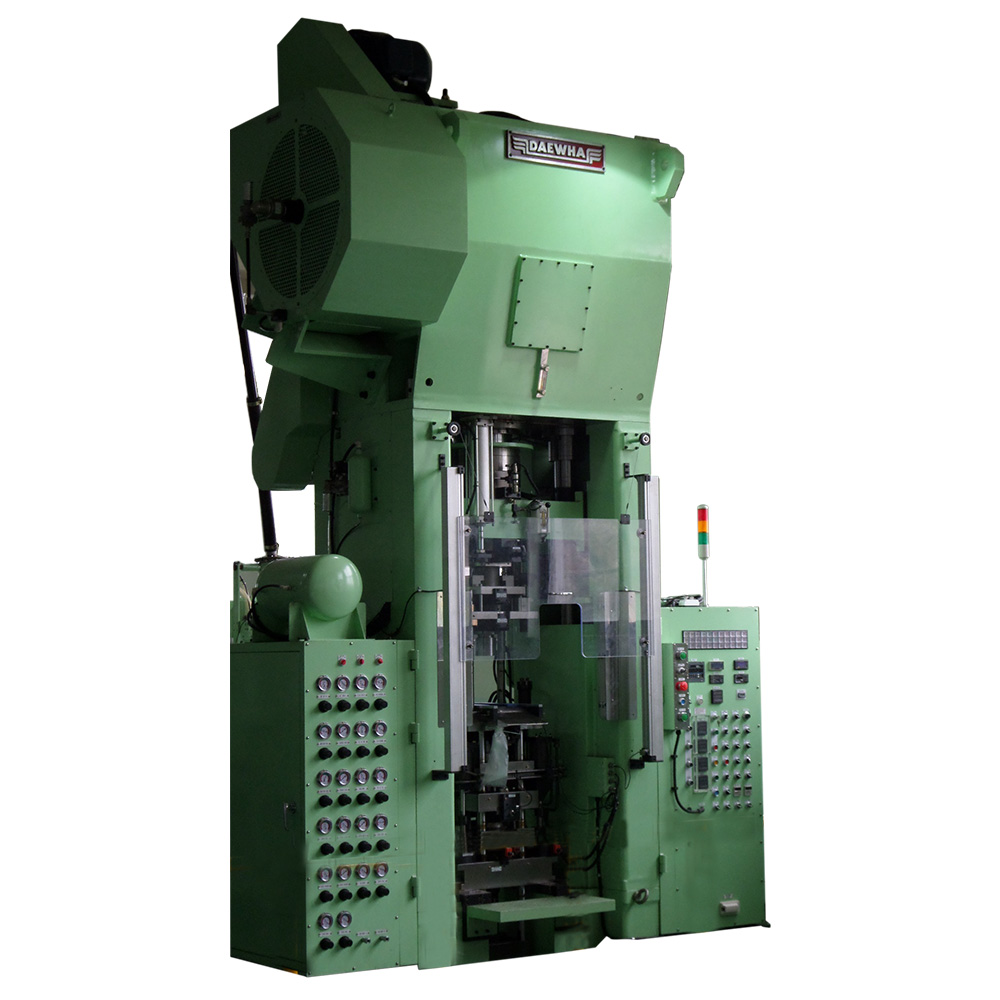

150 TON COMPACTING PRESS

DMC-150_Crank 2P Type

150 TON COMPACTING PRESS

DMC-150_Crank 2P Type

- It is a tie rod method with a structure that operates die control and stopper control separately.

- Since the die control device is installed outside of the machine, the compacting can be observed during the process. So, even a beginner can easily understand it.

- The ejection cam and stopper are installed on the left and right of the press. Therefore, the powerful ejection and stopper action can work well balanced.

- It has a wide workspace, and die sets can be installed from both the front and rear. So, it is easy to install the automation and transfer system.

- Using the inverter, it can easily control S.P.M and reduce troubles such as Belt abrasion caused by V-Belt type transmission.

- The upper enclosed structure prevents foreign substances from entering.

SPECIFICATION

Technical Data

| DESCRIPTION | UNIT | DMC-150 |

| 1. Max. Pressing Capacity | ton | 150 |

| 2. Max. Ejecting Capacity | ton | 80 |

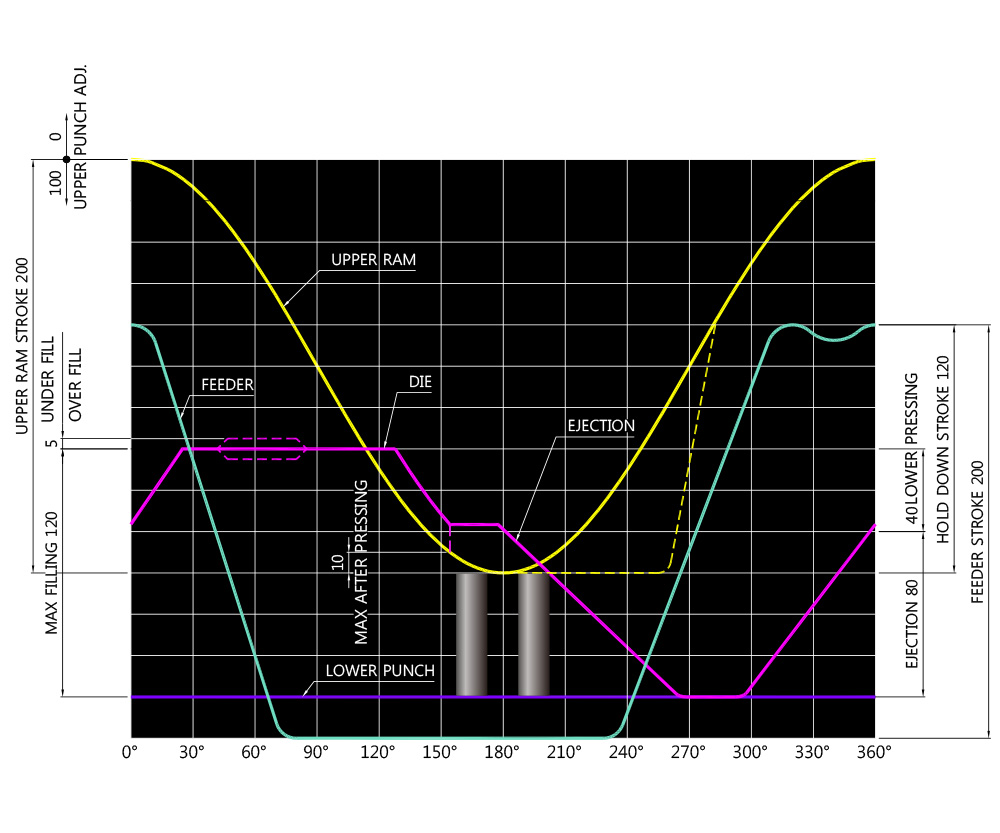

| 3. Max. Filling Depth | mm | 150 |

| 4. Max. Ejecting Stroke | mm | 150 |

| 5. Upper Ram Stroke | mm | 200 |

| 6. Die Control Stroke | mm | 50 |

| 7. Upper Punch Adjustment | mm | 120 |

| 8. Die Face Adjustment Stroke | mm | ±10 |

| 9. Max. Diameter of Compact | mm | 100 |

| 10. Die Stopper Capacity | ton | 75 |

| 11. Compacting Speed (60Hz) | SPM | 8 – 24 |

| 12. Compression indicator | Digital Pressure Gauge | |

| 13. Motor | KW | 22 |

| 14. Speed Changer | Inverter | |

| 15. Clutch & Brake | Spring Return Type / Air Clutch | |

| 16. Lubrication | Centralized Oil Lubrication | |

| 17. Working Air Pressure | kg/cm2 | 5-7 |

| 18. Hopper Capacity (approx.) | liter | 60 |

| 19. Reducer Type | Helical Gear | |

| 20. Net Weight (approx.) | kg | 20,000 |

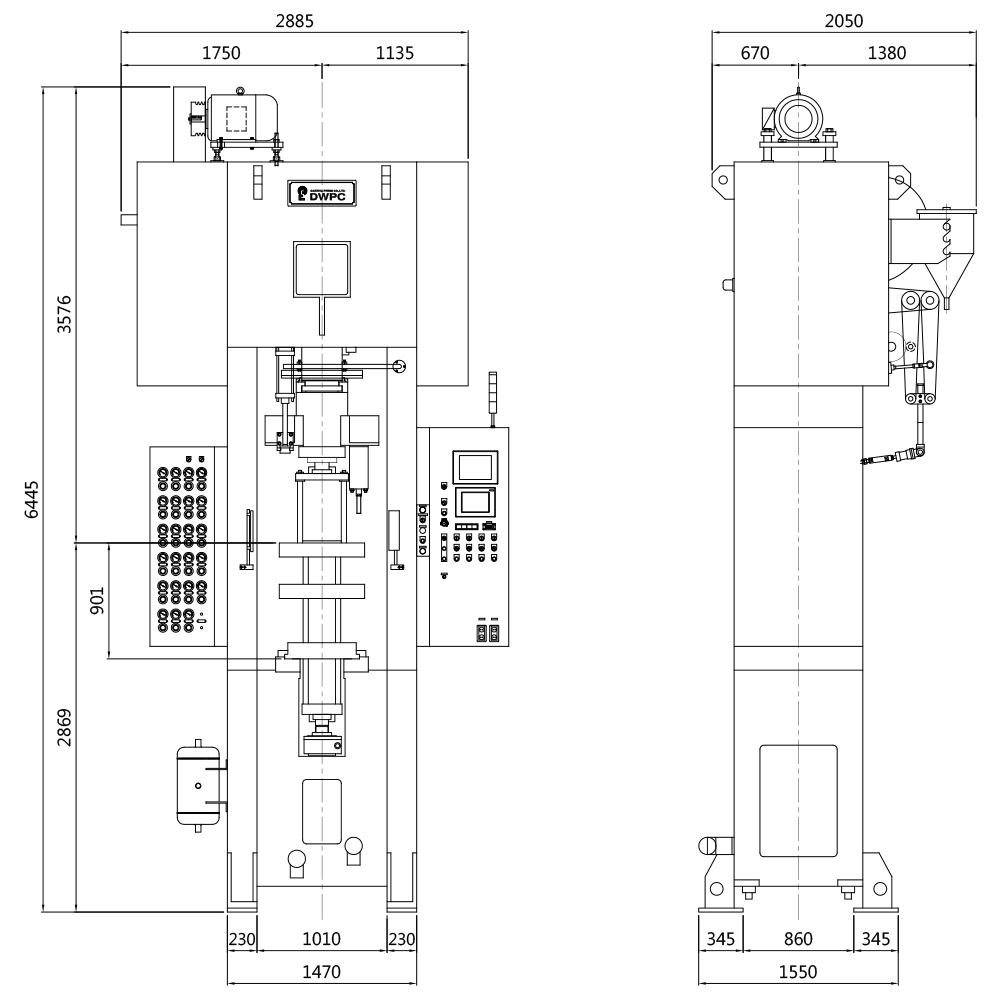

| 21. Dimension (approx.) | mm | H6,445 × W2,885 × D2,050 |