60 TON COMPACTING PRESS

DMC-60_Crank Type

60 TON COMPACTING PRESS

DMC-60_Crank Type

- The actuator placed on the upper part makes it easy to inspect the lower part and install additional equipment.

- Since the die sets can be installed from the rear side, it is easier to replace it. It also allows the automation and transfer systems to be easily installed on the front of the machine.

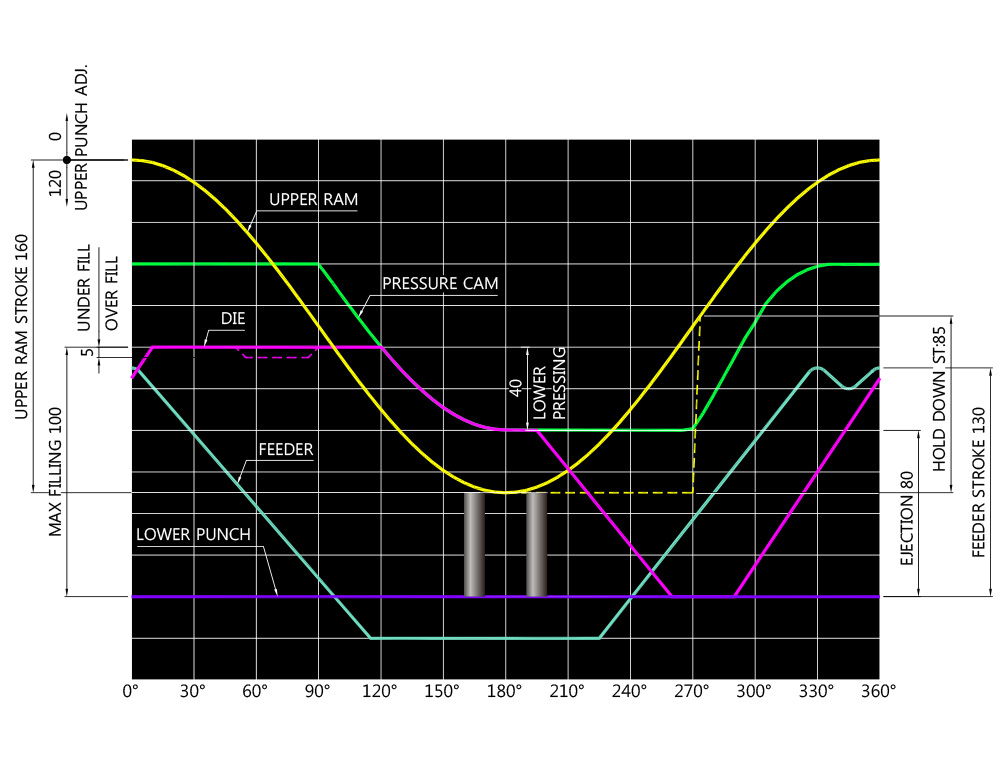

- The product is always ejected on the same place regardless of its depth. It eliminates the adjustment for each product and provides convenience for designing.

- The control device for each part is activated by a motor. So, the operator can easily set the amount for each part with a digital counter on the control panel.

- A long stroke hold-down device is built into the upper ram to control consistent pressing time. It also rises up along with the upper ram for longer and firmer pressing.

SPECIFICATION

Technical Data

| DESCRIPTION | UNIT | DMC-60 |

| 1. Max. Pressing Capacity | ton | 60 |

| 2. Max. Ejecting Capacity | ton | 40 |

| 3. Max. Filling Depth | mm | 120 |

| 4. Max. Ejecting Stroke | mm | 80 |

| 5. Upper Ram Stroke | mm | 160 |

| 6. Die Control Stroke | mm | 80 |

| 7. Upper Punch Adjustment | mm | 120 |

| 8. Die Face Adjustment Stroke | mm | ±5 |

| 9. Max. Diameter of Compact | mm | 100 |

| 10. Die Stopper Capacity | ton | 30 |

| 11. Compacting Speed (60Hz) | SPM | 8 – 24 |

| 12. Compression indicator | Digital Pressure Gauge | |

| 13. Motor | KW | 15 |

| 14. Speed Changer | Inverter | |

| 15. Clutch & Brake | Spring Return Type / Air Clutch | |

| 16. Lubrication | Centralized Oil Lubrication | |

| 17. Working Air Pressure | kg/cm2 | 5-7 |

| 18. Hopper Capacity (approx.) | liter | 60 |

| 19. Reducer Type | Helical Gear | |

| 20. Net Weight (approx.) | kg | 11,500 |

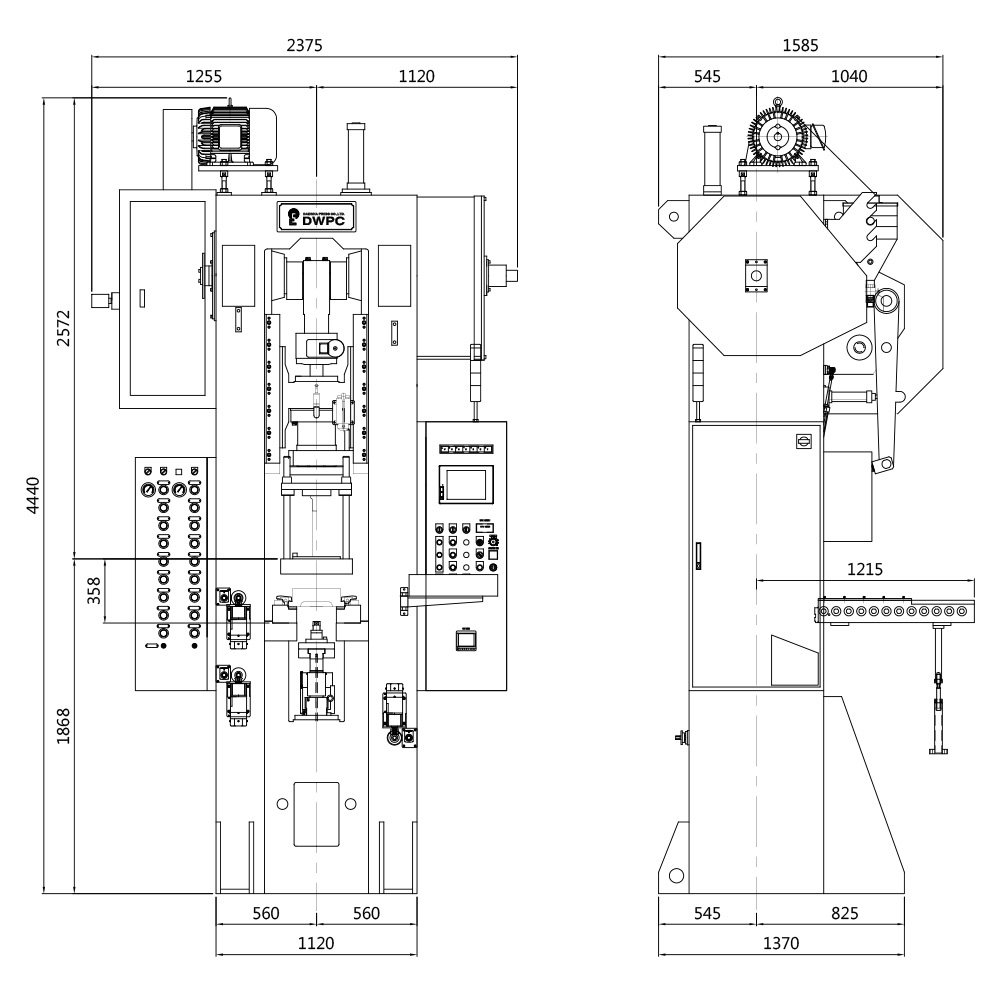

| 21. Dimension (approx.) | mm | H4,440 × W2,375 × D1,585 |